Welcome to the official website of Genesis Innovations!

No more

Welcome to the official website of Genesis Innovations!

The grating is manufactured with the most advanced high-voltage resistance forge welder available in the world, equipped with computer control. Robot arm of the machine can automatically place cross rods (twisted square or round bars, same as below) on load bars arranged uniformly and press them into load bars with strong electric welding power and hydraulic pressure, thus manufacturing high- quality grating with firm welding points, high stability and strength. While a hand-welded grating is made in such a way that holes are punched on load bars firstly, and then cross rods are inserted into these holes for spot welding. In this case, as gaps exist between cross rods and load bars, and some welding points may be neglected during welding, the final product is normally untidy in appearance and low in strength.

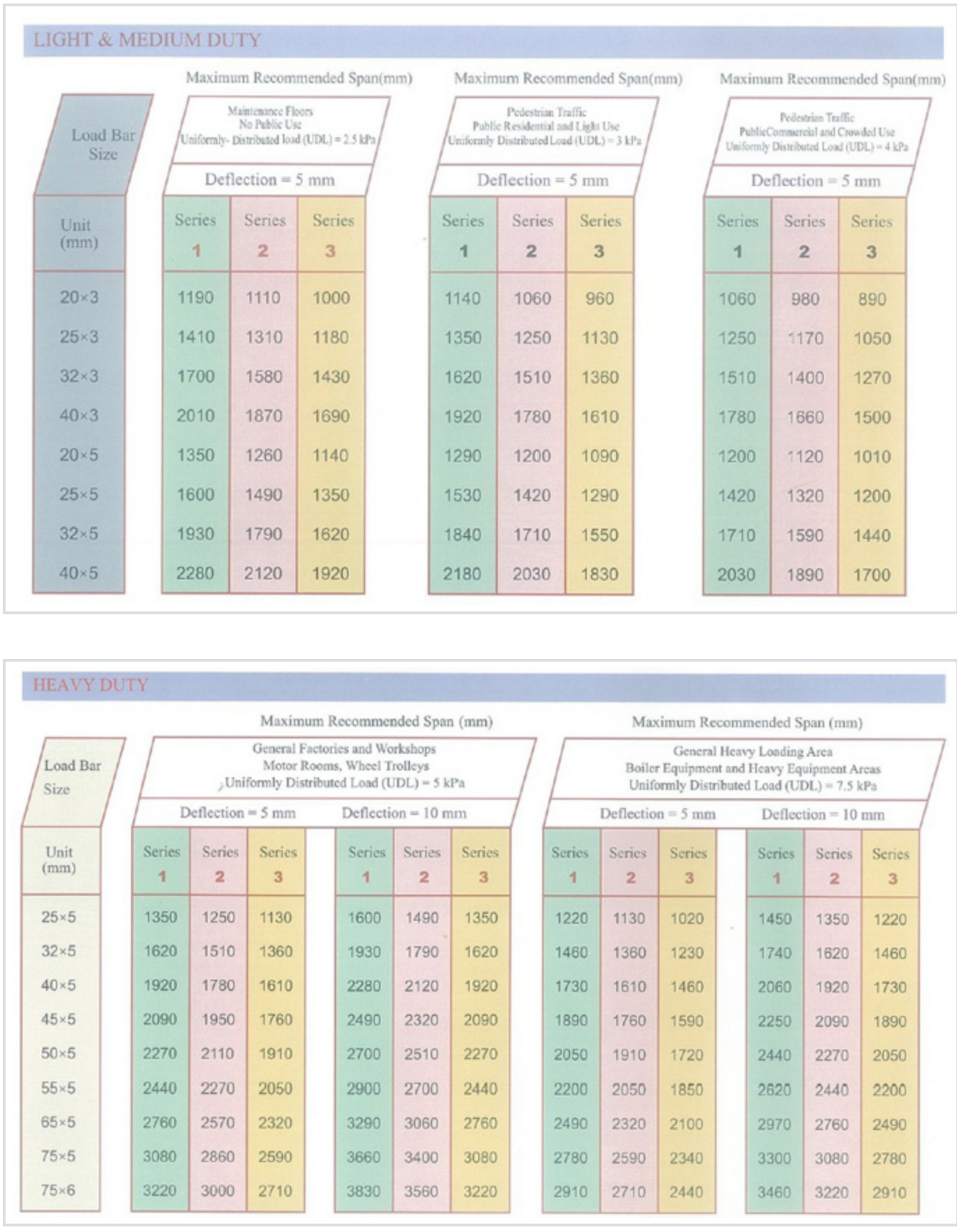

| Besides specifications recommended below, other specifications are also available for design and manufacturing, which will depend on the quantity and delivery schedule requested. All details should be indicated in the contract after agreement of both parties. For relevant duty parameters of stainless steel grating, please refer to "Loads and Deflections Table of Carbon Steel Grating". |

to other standard as agreed by both parties (Buyer and Seller).

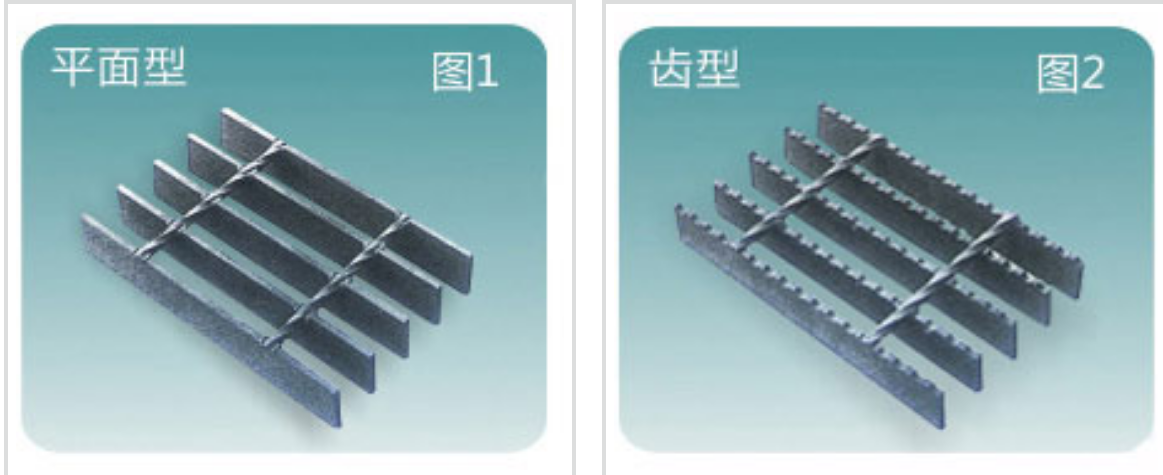

Plain:Plain grating is the standard type most commonly used, skid-proof to some degree.

Serrated:With a sound anti-skid property, serrated grating is normally used on greasy offshore platform and equipment operating station etc. This type has a lower strength. Please refer to "Load and Deflection Table of Grating".

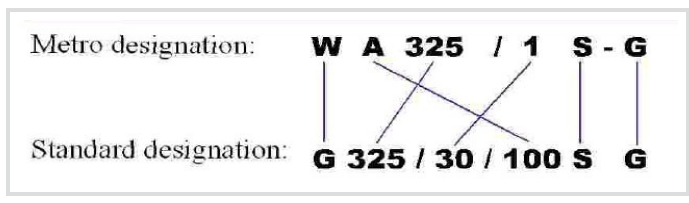

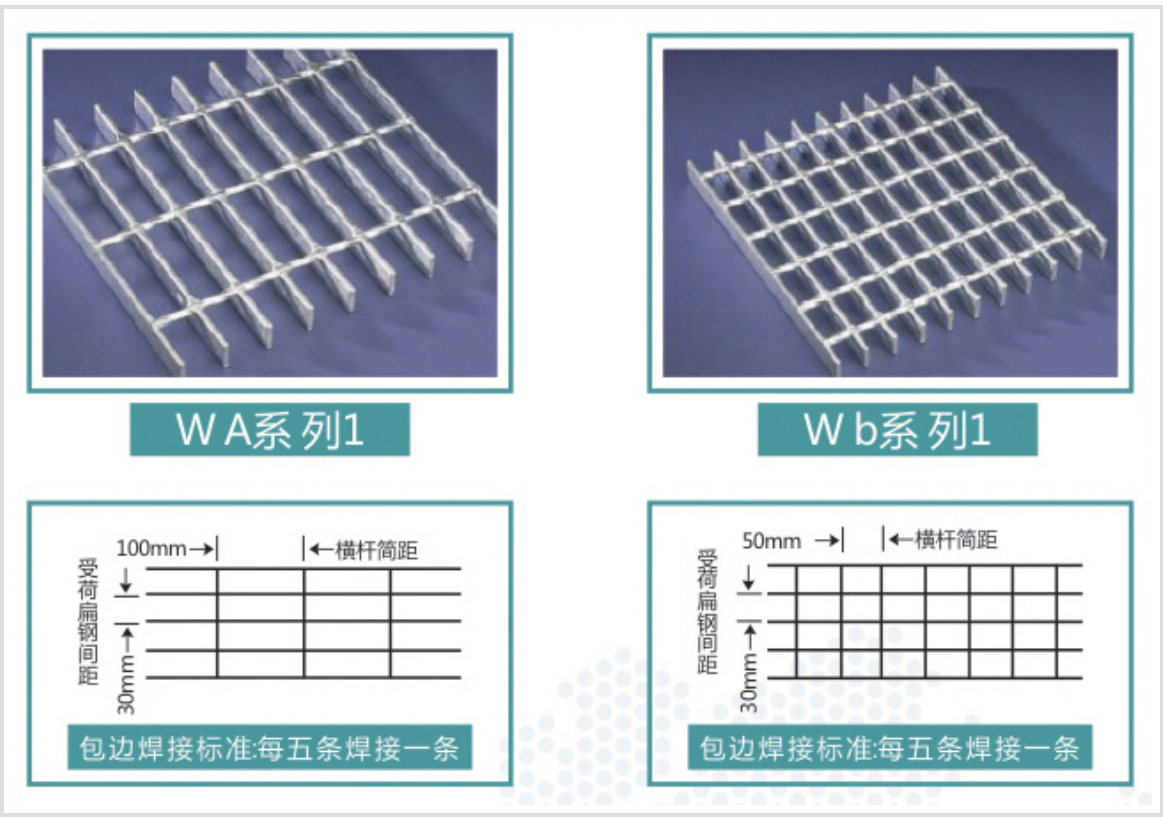

Series 1 : This series is most commonly used throughout all sections of industry. Center pitch of load bars is 30mm. It is in accordance with USA standards, Australia standards and Japanese standards applicable etc. With highest density of flat bars and strength, it is suitable for different applications.

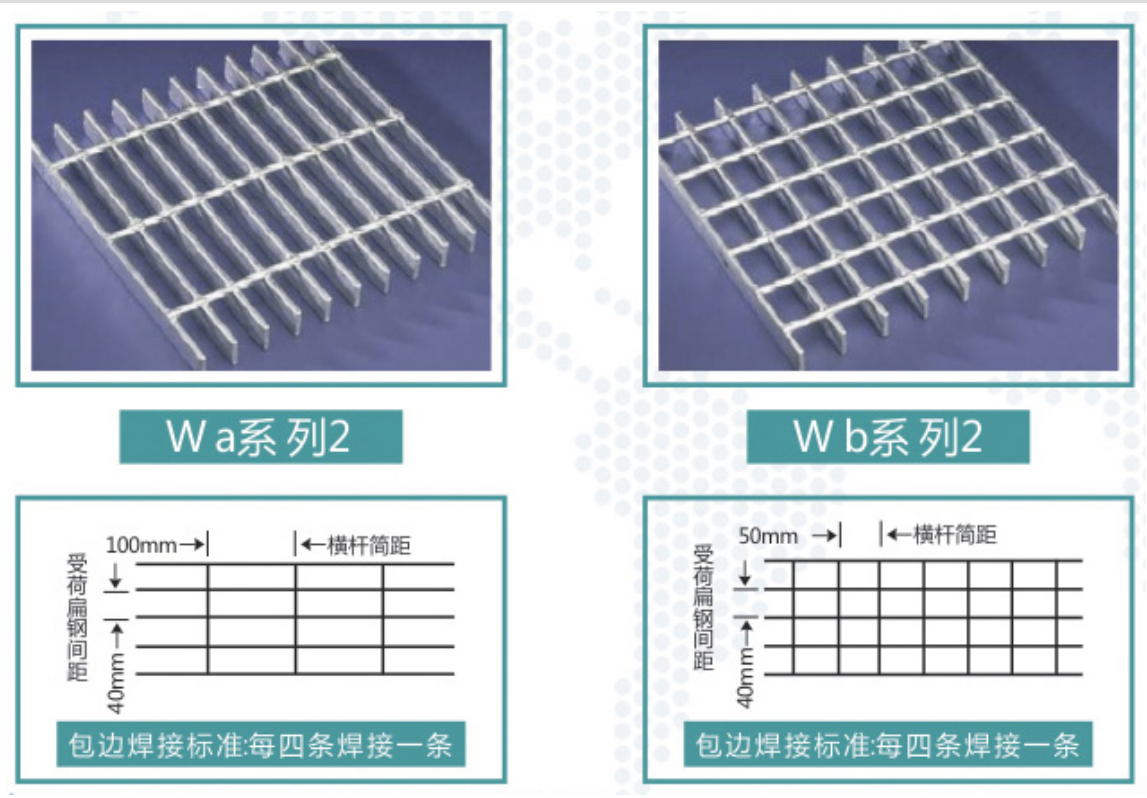

Series 2: This series is most economical and light. Center pitch of load barsis 40mm. It conforms to the requirement of Fixed Platform, Walkway, Stairway and Tread as regulated in British, Germany, France and Japanese standards etc. Its general applications include conveyor walkway, storage shelves, mezzanine floor, catwalk, security grilles and sun screens etc.

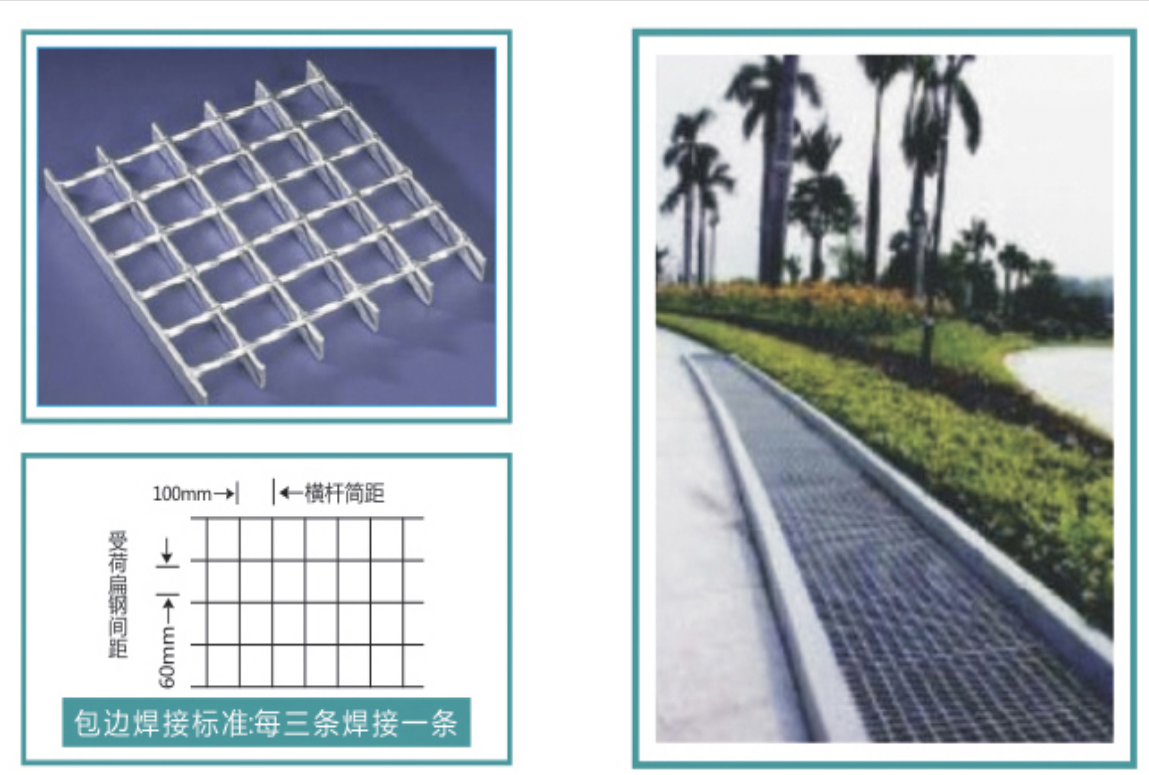

Series 3 :This series has been specifically developed for mining industry and used for hang ceiling Center pitch of load bars is 60 ram. The large square opening allows most materials to fall through the grating, thus keeping the walking surface clear and safe. This product is frequently specified for mining and mineral processing projects. With a high cost efficiency, it is the optimal choice for Hang Ceiling.

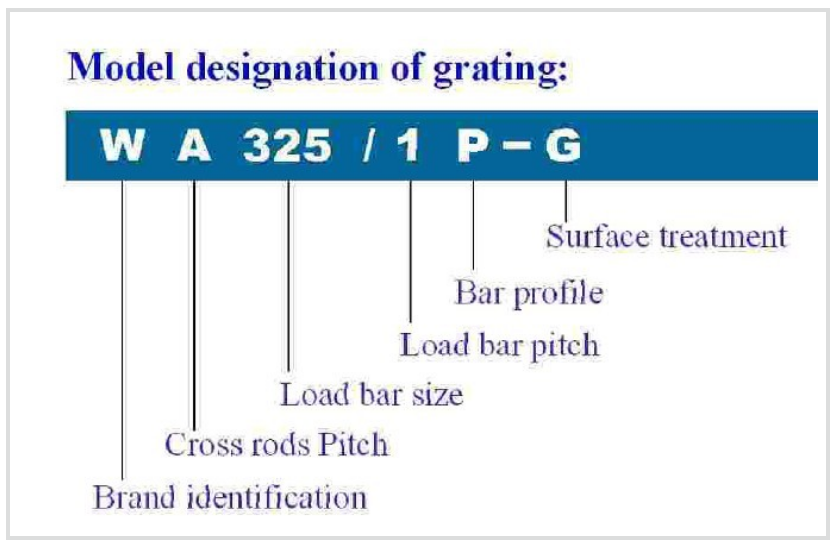

Cross Rod Pitch:

A 100 mm (center distance)

B 50 mm (center distance)

C 25 mm (center distance)

Cross Rod Size:

Generally 6 x 6 twisted rod

5 x 5 twisted rod for small size grating

5round bar for stainless grating

Load Bar Size:

Usually 20 x 3 mm ~ 90 x 7 mm

Load Bar Pitch:

Series 1 30 mm (center distance)

Series 2 40 mm (center distance)

Series 3 40 mm (center distance)

Load Bar Top Surface:

P refers to common plain type (as default, see figure 1 below)

S refers to reinforced anti-skid serrated type (see figure 2 below

I refers to load bar with I- shape section

Surface Treatment:

G refers to hot- dip galvanizing;

P refers to dip painting;

U refers to no surface treatment (as default)

E refers to electrochemical polishing

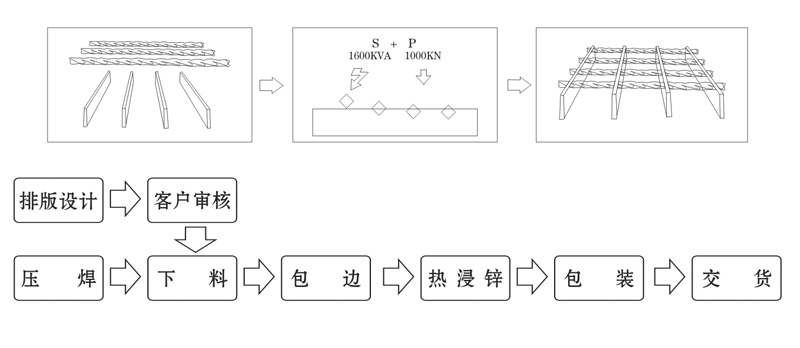

WEBFORGE grating is dimensioned as per design drawing. Prior to packing and delivery, it should be banded first, and then hot-dip galvanized or treated otherwise. Processing flow chart of grating is shown as figure below.

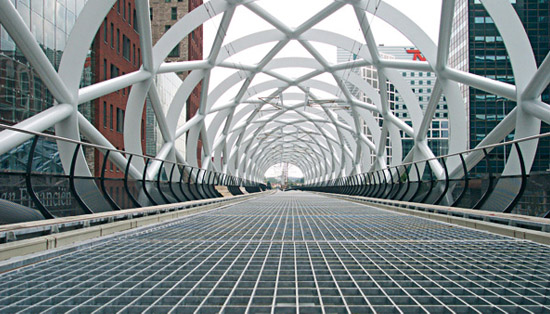

And the pattern plate and other grid comparison, China Fugang grid plate has the following advantages:Save material:the material under the same loading condition. Accordingly, can reduce the supporting structure of the material.Reduction of investment: materials, save labor, save time, free cleaning and maintenance.The construction is simple: in the installation of support with bolt clamping, one person can finish.Save time: product without on-site processing, installation is very quickly.Durable: before galvanizing antiseptic treatment, impact resistance and stress ability.Modern style: appearance, design specifications, air and light, give a person with modern sense of the overall smooth.Light structure: less material consumption, light structure, and easy lifting.

To prevent accumulation of dirt: accumulation of rain, snow and dust.

To reduce the wind resistance: due to good ventilation, windy wind resistance, reduce wind damage.

The design is simple: no small support beam, simple structure, simplified design; no need to design a steel lattice plate details, stating only models, manufacturers and customers can design layout.

Ventilation, lighting, explosion-proof, heat dissipation, good antiskid performance.

Related recommendations